Screen printing is one of the oldest and most versatile printing techniques, which has gained popularity due to its flexibility and the ability to print on various materials, such as fabrics, glass, metal and paper. This technique involves forcing paint through a screen onto the surface of the substrate, which allows for the production of durable, expressive patterns in many colors.

The screen printing technique has its roots in ancient China, where it was used to produce fabrics. Screen printing appeared in Europe in the 18th century and was mainly used to print on fabrics and paper. In the 1960s, screen printing became popular in the advertising industry, and in the 1970s and 1980s it gained popularity in the clothing industry.

How does screen printing work?

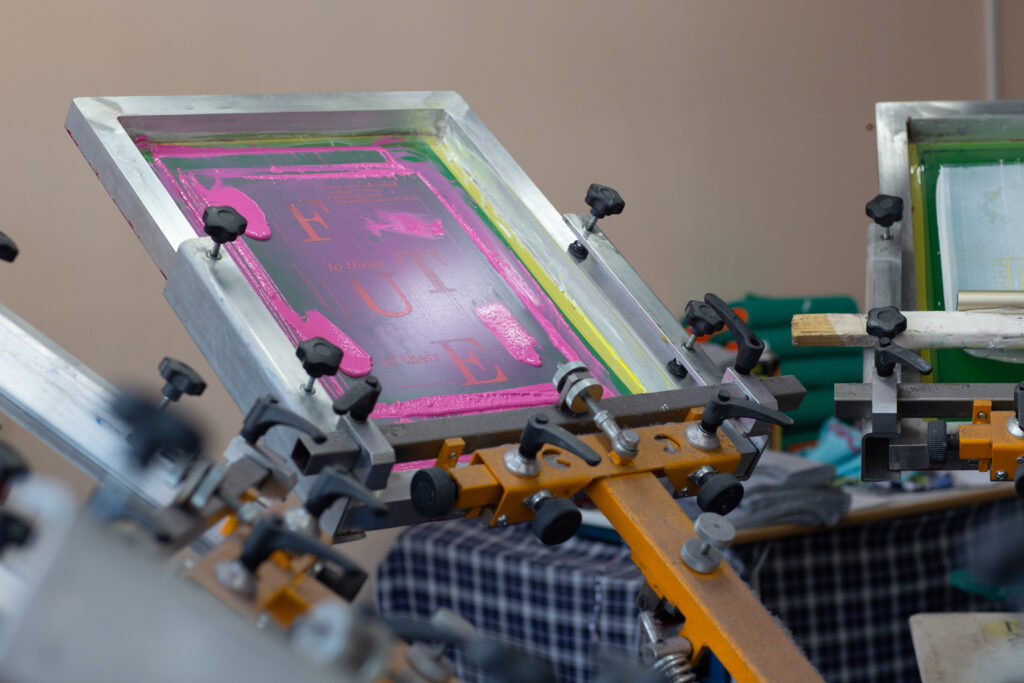

The screen printing process begins with the creation of a matrix, or screen, on which a template, or film with a selected pattern, is placed. The screens are then covered with emulsion fluid and the template is exposed, which allows the pattern to be fixed in the emulsion. After exposure, the frame is washed with water, which exposes the invisible parts of the emulsion, which will be passed through the ink during the printing process. During printing, the ink is squeezed onto the matrix, then pressed through the sieve holes and applied to the substrate. After each pass of the screen printing ink, the matrix is cleaned to allow further printing.

Screen printing process (step by step)

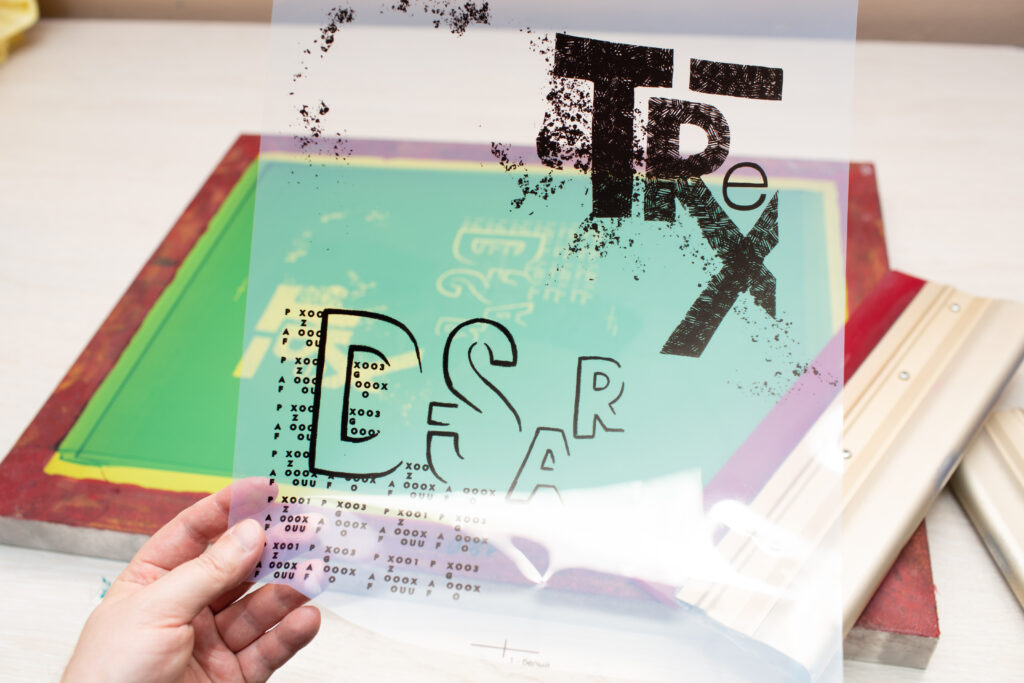

1. Creating a matrix

The screen printing process begins with the creation of a matrix, or screen. Depending on the application and size of the pattern, different types of screens are used. The matrix can be made of metal or plastic and is covered with a special emulsion fluid that is sensitive to light. Then, a stencil, or foil with the selected pattern, is applied to the matrix and glued to the screen.

2. Matrix exposure

After applying the pattern, the matrix is exposed to light in a special machine or under a UV lamp. In this process, the pattern is transferred to the screen emulsion, which allows it to be fixed in the matrix.

3. Matrix cleaning

After exposure, the matrix is washed with water, which causes the invisible parts of the emulsion to be exposed, and the remaining emulsion, which covers the pattern, hardens and creates a barrier for the paint.

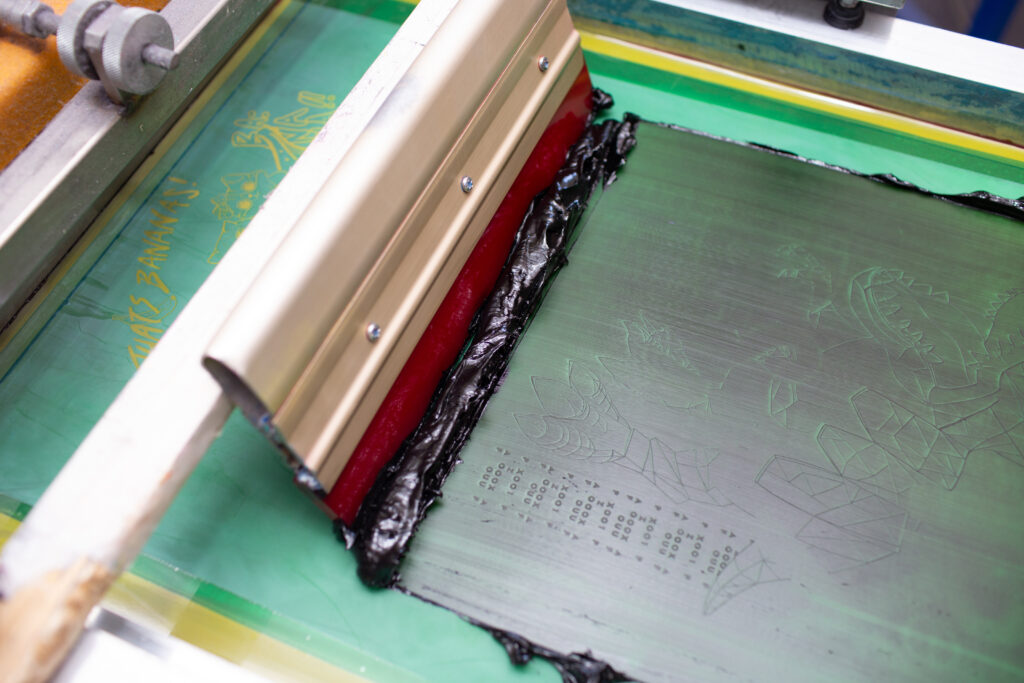

4. Applying paint

After the matrix is prepared for printing, screen printing ink is applied to the matrix and evenly distributed using a special squeegee. The ink is squeezed through the screens, passes through the screen holes and is applied to the substrate surface. In the case of fabric printing, a special conical plater transfers the ink from the matrix to the fabric.

5. Paint curing

After the paint has been applied, it must be cured. In the case of printing on fabric, the screen printing paint is dried for several hours or subjected to a special heat treatment at a temperature of about 160 degrees Celsius. In the case of printing on other materials, the paint may be cured in a different way.

6. Cleaning the matrix

After printing is complete, the matrix is cleaned of any remaining paint. First, excess paint is removed using a special spatula or squeegee, and then the matrix is washed with water under pressure to remove any remaining paint and emulsion. After washing, the matrix is ready for reuse.

Screen printing applications

Screen printing is widely used in the advertising, clothing, decorative and artistic industries. It can be used to print on fabrics, glass, metal, paper, wood and many other materials. In the clothing industry, screen printing is often used to print on T-shirts, sweatshirts, pants and other clothing items. In the advertising industry, screen printing is used to produce banners, posters, stickers, calendars and many other promotional products. In the field of art, screen printing is often used to print pictures and posters.

Advantages of screen printing

- High print quality – by forcing the paint through screens, you can obtain durable, expressive patterns in many colors

- Flexibility – the screen printing technique allows you to print on various materials, which makes it versatile and universal

- Ability to print on large surfaces – screen printing allows you to print on large surfaces, which is particularly useful in the production of posters, banners and other advertising products

- Ability to print on dark fabrics – by using screen printing inks with a white base, you can obtain good printing results on dark fabrics

- Durability – screen printing inks are very durable and resistant to abrasion and weather conditions

- Low costs for large print volumes – screen printing is more cost-effective than other printing techniques for large print volumes, because the unit cost of printing is lower.

Summary

Screen printing is a versatile and versatile printing technique that offers many advantages, such as high print quality, durability and flexibility. Screen printing is particularly useful in the production of clothing, advertising and artistic products. However, this technique also has some disadvantages, such as limited resolution, long preparation time and high costs for low print volume. For this reason, the choice of printing technique depends on the needs and requirements of the specific production.